Transportation Stage.

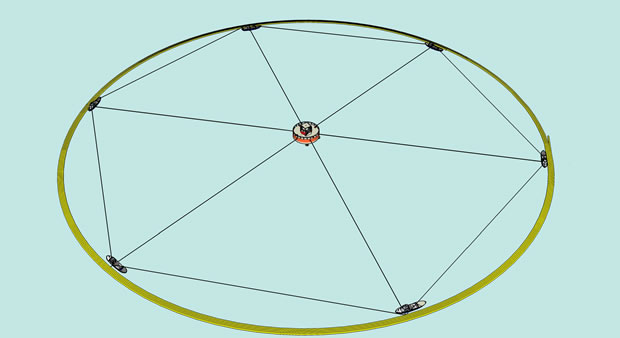

Consider the pipeline has been spiralled over its complete length of several

kilometers. Some “transport” ropes can be attachedto reduce the tension in the

pipeline during its voyage.

When the anchor lines are detached from the centre point the spiral can

be towed to the installation location. The pipeline can be propelled by the centre

barge and the auxiliary boats (See figure 6 ) or by some tugboats.

Although the spiralled pipe can withstand for a short period of time rough waves (up to

a certain limit the spiral can stand waves up to 4-5 meter) it is always good to

consider the weather forecasts when the pipe is being transported.

Fatigue

Because the spiral is exposed to the waves that collide with the spiral when it is

exposed to open water we have to consider fatigue. Fatigue is an important factor to

reckon with. The wave height and the frequency that wave heads come by are the

parameters that will affect the heat affected zones (HAZ’s) of the welded pipes.

Fatigue crack propagation Tests have shown that fatigue occurrence with welded

pipe is strongly depending on the existence of planar defects and the frequent

slamming of the waves has a larger impact for higher grade steel then for the lower

grades. Fatigue crack propagation with the spiral pipeline that is for a longer period on open sea needs more investigation.  Although the O-lay method needs a relative

Although the O-lay method needs a relative

small weather window, the O-lay method is considered at this moment for

geographical area’s where the weather and sea state can be forecasted for the period

of transport and installation. Workable conditions are when the wave height during

transport and installation are preferable below 1,5 meters.

For logistic reasons it is recommended to choose a pipe yard that is in the vicinity of

installation location since the expected speed of travel of the spiral with maximum 5

knots is relatively low.