Pipeline production stage

The pipe girders with a standard length of approximately 12 meter are delivered to construction yard where the pipeline will be fabricated. On arrival at the construction site the pipes will be measured, calibrated (to see if the pipe is not oval or dented during the transport) and cleaned. After the inspection the pipe ends will be beveled by pipe facing equipment and welded into double joints. The double joints are best welded with submerged arc welding stations which can do 2 or more passes depending on wall thickness. Then the pipes will be constructed into quadruple joints also using submerged arc welding. Depending on the layout of the yard and the logistic possibilities the pipe joints can be extended further before they will be moved to the firing line. The orbital welds have to be post weld treated with Ultrasonic Impact treatment or other fatigue resistance raising techniques, tested and coated before the piece of pipeline will be lined up in the firing line.

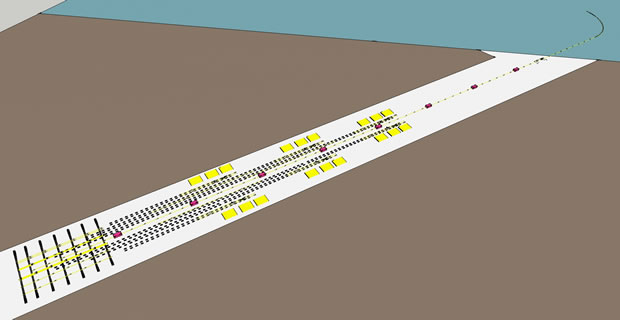

In the firing line the quadruple (or longer) joints will be welded with gas metal arc welding, preferable with a computerized system, the welds will be inspected and the coating will be fixed in place. The production method can differ from the one described since the layout of the production site can be modified to the choice of the production manager depending on its settings, the available equipment and personnel.

Mounting floaters

Often the pipeline is so heavy that it will sink by itself.

For this reason floaters will be mounted to the pipe to assure that the pipe will stay afloat during the spiraling and transport stage. These patented floaters will be of the type that can be easily attached and released in a short time. The design is of a secure fit so that they cannot get loose during transport.

Safe and economic process

Relocation of the welding and inspection of the pipeline from the weather sensitive and remote location offshore to the relatively friendly onshore site is makes working condition safer and is very attractive also due to the lower costs and good approachability to the work site for all kind of services and supply of material which are needed to produce the pipeline.